- Polypropylene spinning machine

- Polypropylene FDY equipment

- Polyester POY spinning machine

- Polyamide FDY common and high strength equipment

- Polyester FDY equipment

- Polyester high strength equipment

- polyester、Polyamide、 Polypropylene BCF equipment

- Small spinning machine

- All kinds of spinning special parts

- Polypropylene FDY spinning machine is a key equipment for the production of high-performance fibers

- Several silk textile industry renewal projects in Shengze have started construction

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter Solstice code is revealed, a dialogue of craftsmanship spanning a thousand years

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productivity Research Institute and the co-construction conference of the textile industry innovation ecosystem were held

- The key points of control in the polypropylene FDY spinning machine process and their relationship with quality

- Contact:Mr. Huang Guofu

- Cel:0086-13901505556

- Fax:0086-519-83341119

- Email:czfb5556@126.com

- Add:No. 288-8 ChangLi Rd, Huangli Town, Changzhou, JS PRV.

01. The textile industry's economic situation is generally stable.

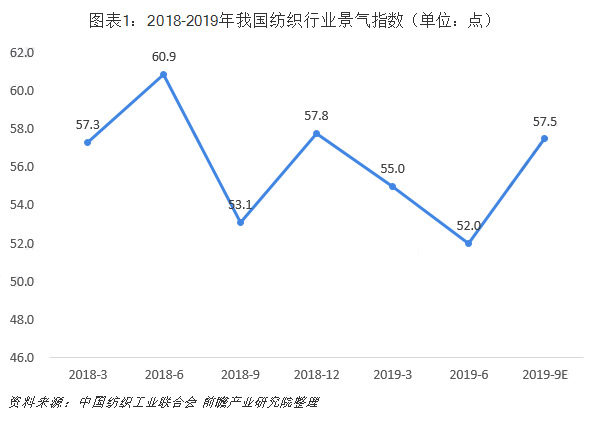

Since 2019, the overall prosperity index of the textile industry has declined, and the confidence of enterprises in the third quarter is still strong. According to the survey data of the China National Textile and Apparel Council, the textile industry sentiment index for the second quarter of 2019 was 52.0, which was 3.0 points lower than the industry sentiment index for the 2019 quarter. Both were above the 50-year-old line, indicating that the industry is still in a growth cycle. It is expected that the textile industry prosperity index in the third quarter of 2019 will be 57.5, which is higher than the current prosperity index, indicating that textile enterprises will have confidence in the operation of the industry in the next quarter.

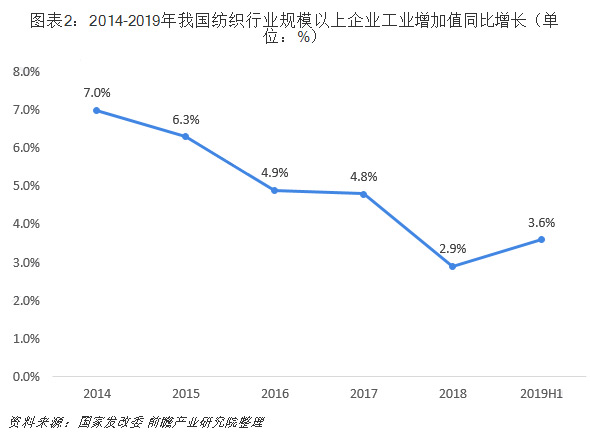

In the first half of 2019, the industrial added value of enterprises above designated size in the textile industry increased by 3.6% year-on-year, which was 0.8 percentage points higher than the same period of the previous year, but slowed by 1.8 percentage points from the first quarter of 2019. Among the various links in the industrial chain, the industrial added value of the chemical fiber industry maintained a 13% double-digit growth rate, which was 6.4 percentage points higher than the same period of the previous year; the industrial added value of the industrial textile industry grew more steadily, with a year-on-year growth rate of 7.6. %.

02, the overall growth rate of the industry has rebounded

Since 2018, the textile machinery industry has intensively promoted industrial upgrading, and has made various progresses in various aspects such as new high efficiency, low energy consumption, flexibility, automation, digitization, and intelligence. Technological innovation and structural adjustment have supported the steady growth of the industry. . Since 2019, the overall operation quality has been good, and the growth rate of the industry has rebounded. From January to March 2019, the enterprises above designated size in the textile machinery industry realized operating income of 22.982 billion yuan, an increase of 14.57% over the same period; total assets were 102.501 billion. Yuan, an increase of 8.56% compared with the same period in 2018.

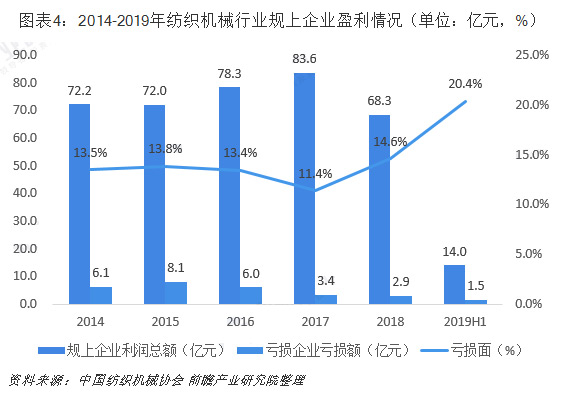

03, industry profitability continues to remain stable

Since 2019, the profitability of China's textile machinery industry has remained stable. From January to March 2019, the total profit of enterprises above designated size in the textile machinery industry was 1.401 billion yuan, an increase of 13.01% compared with the same period of 2018; the loss of loss-making enterprises was 145 million yuan, compared with the same period in 2018, a decrease of 24.05%; the loss side was 20.35%. From January to March 2019, the operating profit margin of the textile machinery industry was 6.10%, a decrease of 0.10 percentage points over the same period of 2018.

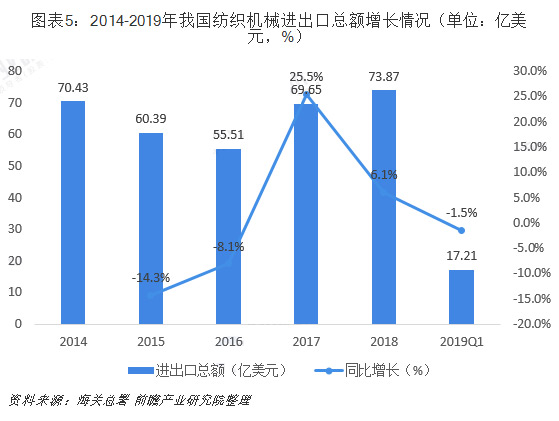

04, the total volume of imports and exports showed steady growth

Since 2015, the total import and export volume of China's textile machinery has shown steady growth. According to customs statistics, the total import and export of textile machinery in China from January to March 2019 was US$ 1.721 billion, a decrease of 1.50% compared with the same period of last year. Of which: textile machinery imports were 819 million US dollars, down 4.69% compared with the same period of 2018; exports were 902 million US dollars, an increase of 1.58% compared with the same period of 2018.

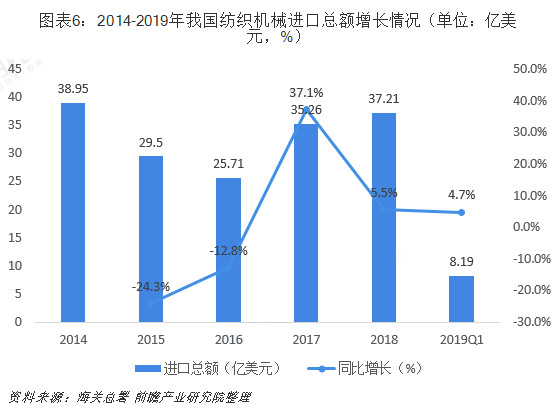

05, the import market maintains a high growth rate

With the industrial transfer and upgrading, and the growth of downstream demand, textile machinery maintained a high import growth rate. From January to March 2019, textile machinery was imported from 58 countries and regions, with a total import value of 819 million US dollars, a decrease of 4.69% compared with 2018. The main importing countries and regions are Japan, Germany, Italy, Belgium and Taiwan. The top five import trade volume is 698 million US dollars, which is 1.83% higher than the same period of 2018, accounting for 85.25% of total imports.

In terms of imported product categories, imports of auxiliary equipment and spare parts ranked first in 2018, with a total import value of 899 million US dollars, an increase of 7.73% compared with the same period of 2018, accounting for 24.16% of total imports; seven categories of products three liters four The increase in auxiliary equipment and spare parts, chemical fiber machinery and weaving machinery is higher than the industry average.

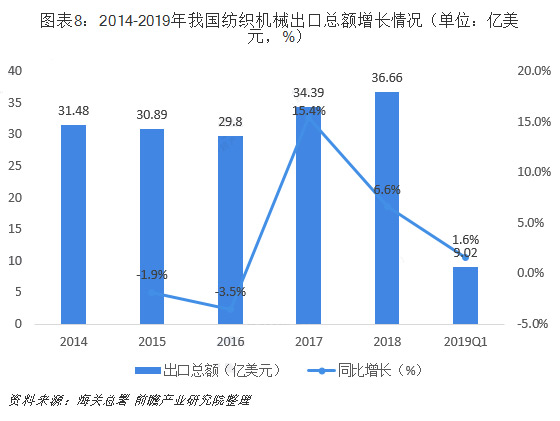

06. The export market growth trend has been delayed

Under the influence of textile companies actively investing overseas, the growth rate of textile machinery exports in the first quarter of 2019 continued its growth in 2018. From January to March 2019, a total of 902 million US dollars of textile machinery were exported to 170 countries and regions, an increase of 1.58% compared with the same period in 2018. The total amount of exports to India, Vietnam, Bangladesh, Uzbekistan and Indonesia accounted for 56.47% of the total export value, which is the main country and region for the export of China's textile machinery. Affected by industrial transfer, the export value of Uzbekistan and Vietnam increased significantly. For the first time, Uzbekistan’s export value ranked the top five in textile machinery exports.

In terms of product categories, the export value of knitting machinery in 2018 was US$956 million, a decrease of 8.24% compared with the previous year, accounting for 26.08%, ranking first, followed by printing and dyeing finishing machinery, auxiliary equipment and spare parts. Spinning machinery, weaving machinery, chemical fiber machinery and non-woven fabric machinery, seven major categories of products in addition to knitting machinery have grown, chemical fiber machinery has grown significantly.

07, intelligent must be the future development trend

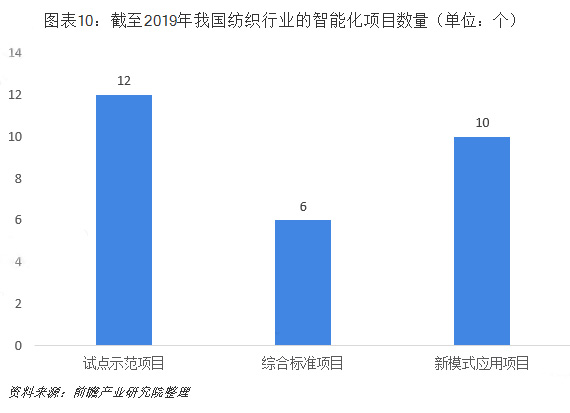

Intelligentization is not only an inevitable trend in the development of textile machinery equipment in the future, but also the most important feature of the development of the textile machinery industry in recent years. As smart manufacturing related technologies continue to be vigorously promoted in the textile field, the textile industry has evolved from the intelligence of stand-alone machines to the digitization, automation and intelligence of systems.

For intelligence, the current government-level guidance direction includes the following four points: establishing demonstration zones; improving smart manufacturing standards; promoting smart manufacturing supplier alliances; and developing Internet+, big data and artificial intelligence. At present, the intelligentization of the textile industry has achieved some gratifying results. At the level of the Ministry of Industry and Information Technology, there were 12 projects listed in the “Smart Manufacturing Pilot Demonstration Project” between 2017 and 2019; in 2018-2019, a total of 6 projects were included. Intelligent manufacturing integrated standardization project; 10 projects were included in the intelligent manufacturing new model application project.

The six intelligent production demonstration lines for spinning, chemical fiber, printing and dyeing, non-woven, knitting and garments proposed by the textile machinery industry have already taken shape, laying a solid foundation for the final realization of the "13th Five-Year Plan".

Changzhou Fubang Chemical Fiber Machinery Factory mainly produces: polypropylene spinning machine, polyester industrial silk spinning combined machine, polyester POY spinning machine, polypropylene FDY spinning machine, polypropylene FDY production line, polypropylene FDY equipment, polypropylene FDY machinery, polypropylene spinning Machine, polyester FDY spinning machine, polypropylene spinning machine, polyester FDY production line, polyester FDY machinery, nylon FDY spinning machine, polypropylene spinning machine.

- Several silk textile industry renewal projects in Shengze have started construction

- Polypropylene FDY spinning machine is a key equipment for the production of high-performan

- The Winter Solstice marks the rise of Yang energy. In Fubon spinning machines, the Winter

- The establishment conference of Guangzhou Modern Textile and Garment New Quality Productiv

- The key points of control in the polypropylene FDY spinning machine process and their rela

- A Guide for Managers to Break Through: Empowerment Rather than Control: Helping Enterprise

- The 2025 Textile and Garment Innovation Annual Conference and the Gongqingcheng Down Indus

- The technological upgrade of polypropylene FDY spinning machines empowers the production o

- Textile News: Full-chain Efforts + Cross-border Breakthroughs + Talent Foundation - The Te

- The 2025 China Home Textile Fashion Innovation Conference grandly kicked off in Binzhou